Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.

Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.

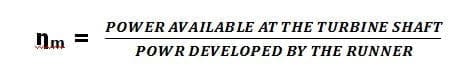

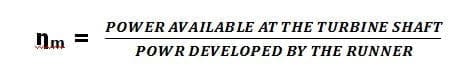

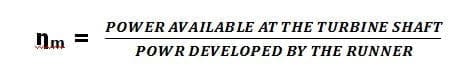

And this process makes it an impulse turbine. This produces an impulsive force on bucket. It would reduce the power output and the overall efficiency of turbine. So this mechanism acts as a speed governing mechanism of Pelton wheel. The runners consist of a circular disk with appropriate semi-elliptical cups known as buckets that are evenly positioned around its circumference. Lets consider 2 different operating conditions. Hey, I am Rajkumar. This turbine was discovered by the American engineer L.A. Pelton. One of the most important parameters of the Pelton turbine design is the number of buckets on the disc. The main objective of the nozzle is to convert the potential energy of the water into kinetic energy. The water flow reduces when the movement of the spear is forward. When the spear is moving toward the nozzle, the water flow rate through the nozzle decreases, and when the spears are moved away from the nozzles, the water flow rate through the nozzles increases. It prevents the runner of turbine attaining unsafe speeds called runaway speed. The deflection angles are the angle of deflection of water after the beak hit. Due to the inertia, the impeller is observed to rotate for a considerable time before stopping. The splitter splits the jet of water striking the buckets into two equal parts and the jet of water comes out at the outer edge of the bucket. This whole article is about the Pelton wheels turbine. What is Heat Exchanger? Unlike other turbine casing, the Pelton turbine casing has no hydraulic function. This kinetic energy drop is the maximum energy the bucket can absorb. A Pelton wheel water turbine is also a well-known type of turbine from the impulse turbine category. Breaking jet includes in the major components of the Pelton wheel turbine. One or more nozzles are placed so that each carries a jet along a tangent to the circles through the centers of the buckets, called the pitch circle. What kind of turbine is a Pelton wheel turbine? It provides safety to the internal parts of the turbine if something falls on the body. Since it only works in high heat, it is difficult to control the vibration in the operating head. In the hydroelectric power plant, first of all, the water stores at high places (as shown in the above diagram). So, these are. Save my name, email, and website in this browser for the next time I comment. These turbines are less dependable as compare to. So with respect to jet to bucket speed ratio, power extraction will vary with as shown below. Blade outlet angle close to 180 degree is usually used in order to maximize impulsive force. What is the efficiency of Pelton turbine? When the water exerts force in the turbine, the turbine starts rotating due to this impulse force. The runners are present in the center, and buckets are placed around the bucket. A turbine in which the water jet hits the wheel tangentially is called a Pelton wheel turbine. In a Pelton turbine, the energy extracted from the kinetic energy of the water is used for the rotation of the impeller."}}]}. The spear is a conical needle present in the nozzle. The primary purpose of this component is to control or adjust the amount of water flowing through the nozzle, as shown in the figure. This is a high-head turbine. Sabin Mathew, IIT Delhi postgraduate in mechanical engineering.  Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.

Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.

Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.

Pelton turbines/wheels are suitable for power extraction, when the water energy is available at high head and low flow rate. The casing also prevents the water from splashing. In this type of turbine, high-speed jets of water emerge from the nozzles that surround the turbine. A cut is provided on bottom portion of buckets. However, a casing is provided to prevent the splashing of water and lead the water to tail race, and to safeguard the persons against accidents. The area in which the whole assembly is fitted is called the turbine cover. So power extraction is maximum when product of impulsive force and bucket velocity is maximum. He provide quality engineering education on his YouTube channel. Your email address will not be published. So the turbine is also called a less specific heat turbine. If you need any more help related to this topic, you can let me know in the comment box. The runner with buckets is shown in the figure given below. The penstock is a channel or pipe to deliver water to the Pelton turbine. In simple words, in the Pelton wheel turbine, the water strikes the wheel or impeller in a tangential direction. However, the runner continues to rotate due to its inertia for a considerable period of time till it comes to rest. What Are the Most Common Factors in Collisions Between Commercial Trucks and Automobiles? In 1870, an American developer Lester Allan Pelton invented the Pelton wheel turbine. Water is stored at a high head & passes through the Penticton, and reaches the nozzle of the Pelton turbine. What Happens to Your Car in a Wrecking Yard? Which turbine use for high head and low flow rate? The jet of water from the nozzle strikes the buckets (vanes) of the runner. The splitting of the water into the cups helps to balance the turbine because the component of the force exhaled by the water is canceled after splitting because these components of the force are equal in magnitude & opposite in direction. Sabin is a very passionate about understanding the physics behind complex technologies and explaining them in simple words. efficiency volumetric turbine of the water and directs the water in the form of a jet. This momentum works on the. The first position of the spear head produces a low flow rate, while the second position produces a high flow rate. The commonly adopted dimensions of bucket are : L = Length of height of bowl inside the rim = 2 d to 3 d, B = Width of bucket between the rims of bowl = 3d to 4d, Sodium Vapour Lamp Construction and Working, ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES), Star Delta Starter Controlling Diagram | Working of Star Delta Starter. Your email address will not be published. A cover is provided to prevent water splatter and the tailrace from discharging water. If you need water above the water inlet, the installment of this turbine is an easy and efficient way to pump water. So it is always desirable to operate Pelton wheel at this condition. In these Pelton turbines, there are two openings that help maintain pressure inside the turbine, which is equal to atmospheric pressure. A turbine capable of operating under a high potential head of water is a Pelton wheel turbine that operates at a head over 300 meters. Your email address will not be published. At the same time, the water flow rises when the movement of the spear is backward. The pressure at the inlet and outlet of the turbine is atmospheric pressure. If Pelton wheel buckets are held stationary, there will be a huge impulse force produced. Also, it provides the smooth flow of water with negligible loss of energy A spear is a conical needle which can be moved in axial direction by operating the wheel either manually or automatically. In this type of turbine, the water potential and pressure energy are converted into kinetic energy. This means that this turbine is used only in the situation where water is available at the high head. But theoretically, all calculation is done by taking the inlet angle. When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. The Pelton wheel turbines are used for producing electricity in the hydroelectric powerplant. Force so produced can easily be derived from Newtons 2nd law of motion. The special shape of bucket makes the jet turn almost 180 degree. The spear system is for regulating the flow of water. Read also: Different types of Impulse Turbines. At the last, a generator is connected to the impeller shaft which converts the mechanical energy of the impeller (rotational energy) into electrical energy. So, the Pelton wheel turbine has one only stage of the turbine, unlike gas turbines which are worked with compressible liquids (such as gas). These blades are made of stainless steel, bronze, cast steel, or cast iron. With lowering power demand the spear head at water inlet nozzle is moved in. Pelton turbines can give efficiency as high as 90 %, at optimum working conditions. It acts as a hydraulic brake for reducing the speed of runner. But the y-direction forces of two cups will cancel each other out because they will be equal in magnitude & opposite in direction, but the forces in the x-direction of the two cups will combine and help rotate the turbine. However absolute velocity of fluid will have huge drop from inlet to exit of bucket. The nozzle is a circular guide device that directs the water flow in the design path and adjusts the water flow. How much power can a Pelton wheel produce? This will lead to zero impulse force. So, these are types of turbines that work more efficiently in the hydroelectric powerplant. During the working of the Pelton wheel turbine, the water from the high head transfers into the nozzle of the turbine via a pressure pipe (penstock). Each blade divides the water flow into two parts and balances out the side force or the thrust from the wheel and bearing. | Types of Flames in Gas Welding, Open Belt Drive And Cross Belt Drive | Difference Between Open Belt Drive And Cross Belt Drive, EBM Machining | Principle of Electron Beam Machining | Working of Electron Beam Machining, Difference Between Orthogonal and Oblique Cutting | Orthogonal Machining, Parts of Shaper Machine | What Is the Shaper Machine? Runner is a rotating part of the turbine. When the turbine needs to be stopped, then the nozzle is fully fastened. The impeller starts revolving at an excessive velocity, and the amount of water that hits the blades is regulated with the help of a spear present in the nozzle. It is used for the water available at high head. Each blade has a wall between two hemispherical bowls known as a splitter. There is a tangential flow. And if you like the article then dont forget to like and share it. Water stored at high altitude can easily produce high jet velocity.